In the world of mining and heavy industry, the ground is never truly still. Beneath the surface, every blast sends ripples through rock and air. Shockwaves that can carry consequences far beyond the moment they’re triggered. And when those vibrations edge too close to regulatory limits or sensitive infrastructure, the cost of delay or oversight can be steep.

That’s where Novecom’s Blast Vibration Monitoring (BVM) system steps in, not just as a tool, but as a vigilant partner in environmental compliance and operational safety.

Rather than relying on manual logs or post-event analysis, BVM offers a smarter way forward. It captures and processes vibration data in real time, giving site teams the ability to respond instantly, adjust operations proactively, and maintain confidence in the face of scrutiny.

A Watchful Eye Beneath the Surface

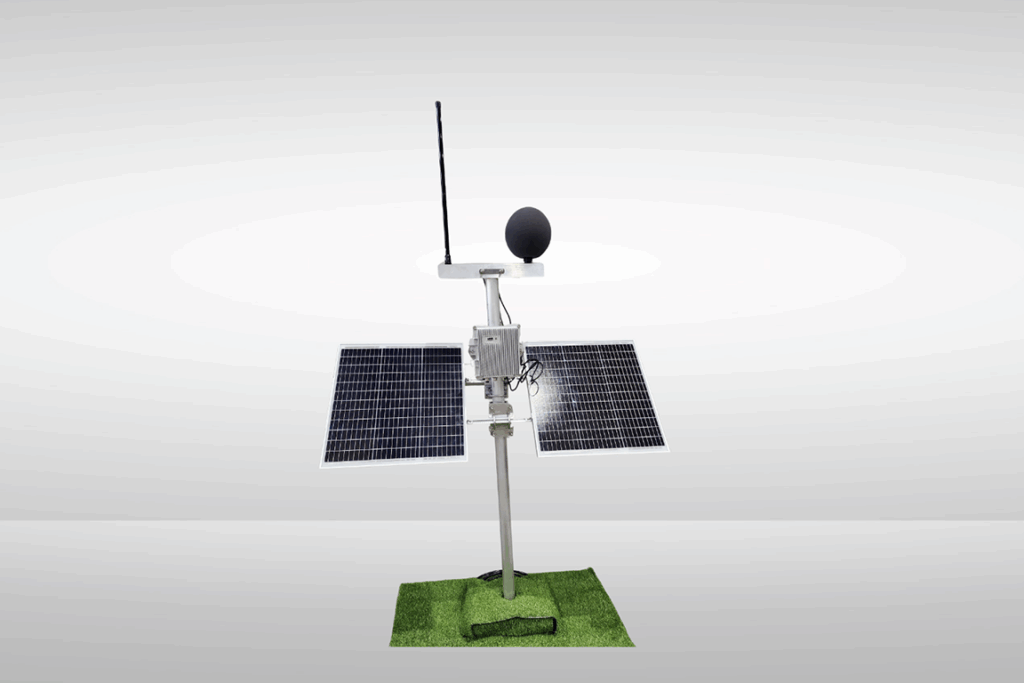

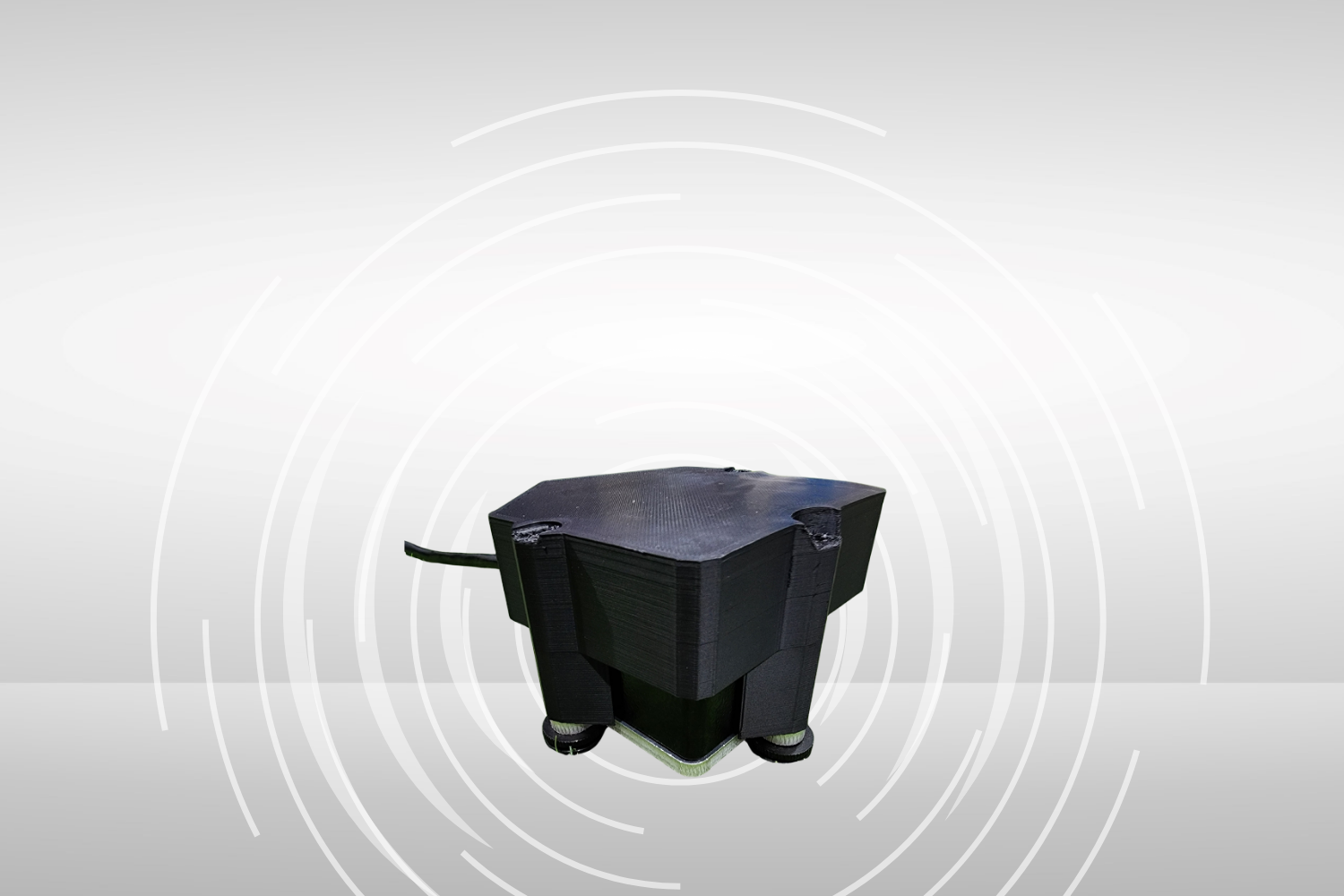

At the heart of the system is rugged, Australian-made state of the art electronics hardware housed in a die-cast aluminium enclosure, built to withstand the harshest conditions. It meets AS 2187.2-2006 standards, and it’s designed to do more than just survive, it’s built to deliver precision.

The unit records peak particle velocity, P, S, and R wave profiles, and air overpressure, along with the exact time and location of each blast event. These data points form a detailed picture of how each blast behaves, how far its effects travel, and whether it’s approaching thresholds that could trigger complaints or regulatory action.

Listening to the Ground and the Air

The system’s triaxial geophone is tuned to detect ground movement in three axis, x, y and z which is then recorded and analysed to determine the strength and direction of the vibration.

Above ground, an omnidirectional microphone captures the shockwaves that travel through the air. Housed in a weatherproof casing, it converts pressure changes into electrical signals, logging peak overpressure in decibels or Pascals. Together, these instruments provide a complete view of blast impacts, both underground and above.

Real-Time Insights, Remote Reach

What sets BVM apart is its ability to deliver insights instantly, even in remote or expansive sites. Using IoT connectivity including LoRa mesh networks, HaLow Wi-Fi, satellite, and cellular gateways, the system operates independently of traditional infrastructure. No towers and no repeaters required in most cases

Operators can access live data through a streamlined desktop app, designed for ease of use with minimal training. Alerts are triggered automatically when vibration levels approach limits, allowing teams to act before problems escalate. Monthly reports are generated without manual input, easing the burden of compliance and freeing up time for strategic decision-making.

Built for Every Industry

While mining is a natural fit for BVM, its applications extend across sectors. In infrastructure projects, it helps protect roads, buildings, and utilities from damage during demolition or construction. In renewable energy developments, it ensures safe blasting near sensitive zones, wildlife habitats, and critical power infrastructure.

Each site presents unique challenges, and Novecom’s system is designed to adapt measuring the variables that matter most, whether it’s ground stability, vibration intensity, or environmental impact.

More Than Monitoring

Ultimately, BVM is more than a piece of equipment. It’s a solution that combines durable hardware, intelligent analytics, and seamless connectivity to deliver peace of mind. With ongoing technical support and the flexibility to integrate with other environmental monitoring systems dust, noise, water, soil, and weather it’s a future-ready platform for industries that can’t afford to fall behind.

In a sector where every blast matters, Novecom’s Blast Vibration Monitoring system offers a steady hand and a sharp eye, always alert, always ahead.

Ready to take control of your blast vibration data?

Reach out to the team to book a free demo and see how real-time monitoring can simplify compliance and boost site safety.