Novecom is helping mine sites stay safe, compliant and informed. Our mobile monitoring and reporting platform, SentineX, is designed to ensure mine sites always stay one step ahead by redefining environmental monitoring.

In a complex sector like mining, every site needs a sentinel – something steady and watchful that never blinks or misses a sign.

In the swirl of dust, noise and vibration that comes with heavy industry, small problems can quickly grow if they go unnoticed. But when environmental limits are tight and scrutiny is high, even a moment’s delay can mean a breach, a complaint, or a halt in work.

Compliance demands more than routine checks and reactive fixes; it requires constant awareness and the ability to respond the moment conditions change.

And that is exactly what Novecom’s SentineX – a platform designed for continuous remote environmental monitoring – brings to the table.

Rather than just a monitoring tool, SentineX feels more like a steady guardian watching over mining sites and heavy industry operations, providing a steady flow of real-time data and instant alerts. This gives teams not only the clarity they need but also the confidence to act swiftly and keep everything running smoothly without the stress of wondering what might be missed.

Take dust monitoring, for instance

In the past, tracking dust often meant occasional spot checks or scrambling to respond only after emissions had already risen.

SentineX flips that script.

Combining rugged, weatherproof hardware with sharp artificial intelligence (AI)-driven analytics, it continuously watches the air with precision. Its fixed dust monitors meet Australian standards, measuring fine particles like PM10 and PM2.5 via two novel methods: one tracks dust build-up by sensing subtle vibrations, while the other sends beta particles through filters to gauge dust concentration.

Portable monitors then use lasers to catch dust in motion, helping teams pinpoint the exact source of trouble before it escalates.

The system’s hardware also seamlessly adapts to site needs, whether mounted high on a pole powered by mains electricity or attached to mobile trailers running on solar energy. It is designed to fit into existing air quality and weather stations, giving operators a full picture of environmental conditions.

Around-the-clock monitoring keeps teams informed every minute, with instant alerts when dust levels climb. Some of those key insights are pulled together in monthly reports, easing compliance burdens and freeing teams from tedious manual work.

Noise monitoring is another vital piece of this environmental puzzle

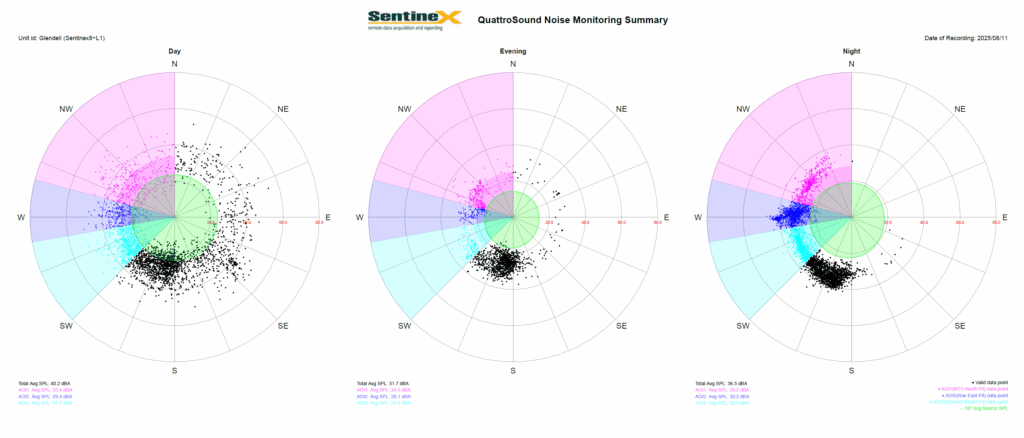

SentineX listens constantly, either through a single microphone that captures sound from all directions or a more sophisticated array of four mics that can identify where noise is coming from and how loud it is.

AI also steps in here, separating industrial noise from background hum to cut false alarms and speed up response. This allows teams to understand not just the volume but the source, helping to prevent breaches and easing potential concerns of any nearby communities.

In a situation where, for example, the buzz of a mine’s overnight haulage suddenly edges closer to noise limits, SentineX’s live monitoring and automatic alerts mean the team can quickly check the dashboard, review recent patterns, and act fast.

Managers can then change truck routes and set up sound barriers, keeping noise in check and community concerns at bay, resulting in a win born from staying ahead rather than chasing problems.

Completing this vigilant watch is blast vibration monitoring

Blasting sends shockwaves through the ground and air, and managing those vibrations is crucial to prevent damage and disturbance. SentineX’s rugged sensors, housed in tough cases, measure vibrations from multiple directions and detect overpressure in the air.

Tracking data like peak particle velocity and vibration profiles in real-time means teams can gain a detailed understanding of blast impacts.

With these insights, operators can foresee hotspots and adjust blasting plans accordingly. In sensitive areas like underground mines near critical infrastructure, this proactive monitoring keeps vibration within safe limits. Automated reports then offer clear, reliable evidence to regulators and neighbours alike, helping build confidence and reduce risk.

These capabilities are all united by SentineX’s intuitive interface and solid support.

The desktop app puts real-time insights and reports at users’ fingertips with minimal fuss. Behind the scenes, ongoing technical support and site visits keep the system finely tuned.

Whether through Internet of Things (IoT) mesh networks, satellite links or cellular connections, SentineX stays reliable even in the most remote and sprawling sites, without the need for towers or repeaters.

By weaving together advanced sensors, smart analytics and seamless reporting, SentineX does more than tick boxes. It helps teams get ahead of problems, protect health, respect communities, and keep operations moving without interruption.

In an industry where every moment counts, SentineX is more than a system; it is the watchful presence on which operators can rely quietly working behind the scenes to keep things safe, steady and ahead of the curve. It’s always there – and it’s always alert.

This article is adapted from ‘Always on guard’ in Australian Mining Safe to Work, September-October 2025, pp.26-27